New Posts

LightHouse UNZIPPED!

08 February 2022

Making a Start

Making a Start

That said, it may be best not to leap up and risk pulling a muscle. First of all, make another cup of tea and have a long think. As we draw up our plans, it will soon become apparent which supplies and equipment will be needed if we are to end up with a successful harvest.

The major decision this year has been to make the transition to LED lighting, chiefly on account of energy costs. But there are side-benefits too, not least of which is the reduction of the heat added to the above-canopy part of the growing environment, where it is of little use to the plants.

A lack of heat would be a problem during the propagation stage of the grow, of course, so that needs to be organised correctly. With the recently introduced EnviroGro by LUMii 60cm 4 Lamp TLED Fixture, hung in the old LightHouse CLONE 1 Tent there will still be plenty of room for a propagator. The TLED Fixture can be set to a cycle of eighteen hours on and six off using a LUMii 24 Hour Heavy Duty Timer.

LED lamps emit little heat, so to achieve a germination temperature around 25°C and then to keep the seedlings comfortable with a night-time temperature above 18°C, a slim and reliable LightHouse ECOHEAT 80W Greenhouse Heater is needed. This can be controlled by a simple plug-and-play LightHouse Wireless Thermostat. That will ensure that the temperature within the propagation tent is kept stable and the heating costs very low, even if it’s set up in an outbuilding or loft. According to the talk at the grow shop, there will soon be a white-lined CLONE Tent available, which might be better suited to LED lights, but that will have to wait until the next crop.When the young plants are under way, the main growing environment can be got ready. This will be in a secure lock-up which has great potential as a grow room. Eventually, the plan is to have it properly insulated, fully lined with LightHouse ULTRALUX Flat Black White sheeting, and partitioned into two separate growing areas, a small propagation room, and a service room for electrics, fans, filters and controls. It already has a washroom/kitchen where the reservoirs sit, and nutrients and additives are stored and prepared. But that’s for the future. Right now, the lock-up is empty and near freezing and there is much to be done.

LED lamps emit little heat, so to achieve a germination temperature around 25°C and then to keep the seedlings comfortable with a night-time temperature above 18°C, a slim and reliable LightHouse ECOHEAT 80W Greenhouse Heater is needed. This can be controlled by a simple plug-and-play LightHouse Wireless Thermostat. That will ensure that the temperature within the propagation tent is kept stable and the heating costs very low, even if it’s set up in an outbuilding or loft. According to the talk at the grow shop, there will soon be a white-lined CLONE Tent available, which might be better suited to LED lights, but that will have to wait until the next crop.When the young plants are under way, the main growing environment can be got ready. This will be in a secure lock-up which has great potential as a grow room. Eventually, the plan is to have it properly insulated, fully lined with LightHouse ULTRALUX Flat Black White sheeting, and partitioned into two separate growing areas, a small propagation room, and a service room for electrics, fans, filters and controls. It already has a washroom/kitchen where the reservoirs sit, and nutrients and additives are stored and prepared. But that’s for the future. Right now, the lock-up is empty and near freezing and there is much to be done. To make the place fit to work in, a LightHouse 3kW Greenhouse Heater blasting out heat from its two powerful elements will soon take the chill off the place, and then maintain a comfortable working temperature while a brand-new LightHouse WHITE 3m² Tent is erected with the help of a friend. It’s certainly a two-person job! Assembling the sturdy steel frame is simple enough but lifting and fitting the durable 600 denier tent canopy needs capable hands at either side of the frame. When it’s finally up, the inside looks like a preview of heaven; brilliant white highly reflective surfaces all round. Very reassuring to see that the new white tents have retained all the great features and detailing of the trusty and familiar LightHouse MAX range.

To make the place fit to work in, a LightHouse 3kW Greenhouse Heater blasting out heat from its two powerful elements will soon take the chill off the place, and then maintain a comfortable working temperature while a brand-new LightHouse WHITE 3m² Tent is erected with the help of a friend. It’s certainly a two-person job! Assembling the sturdy steel frame is simple enough but lifting and fitting the durable 600 denier tent canopy needs capable hands at either side of the frame. When it’s finally up, the inside looks like a preview of heaven; brilliant white highly reflective surfaces all round. Very reassuring to see that the new white tents have retained all the great features and detailing of the trusty and familiar LightHouse MAX range. The tent has four cable entry glands, all double-lined and light tight when the toggles are tightened. Near the base there are six mite-proof passive air vents, with Velcro-fastened light proof covers if not in use. There are four 300mm inline socks (two at each side) for fitting air-cooled lighting, but these are not needed for LED lighting, so they will remain sealed by their Velcro-fastened covers. Two huge doors give access at the front of the tent, and there are also doors at each side and one at the rear. All are fastened with Tivax double-lined, lightproof zippers. If more access was ever required, the whole front of the tent can be opened by simply unzipping it.

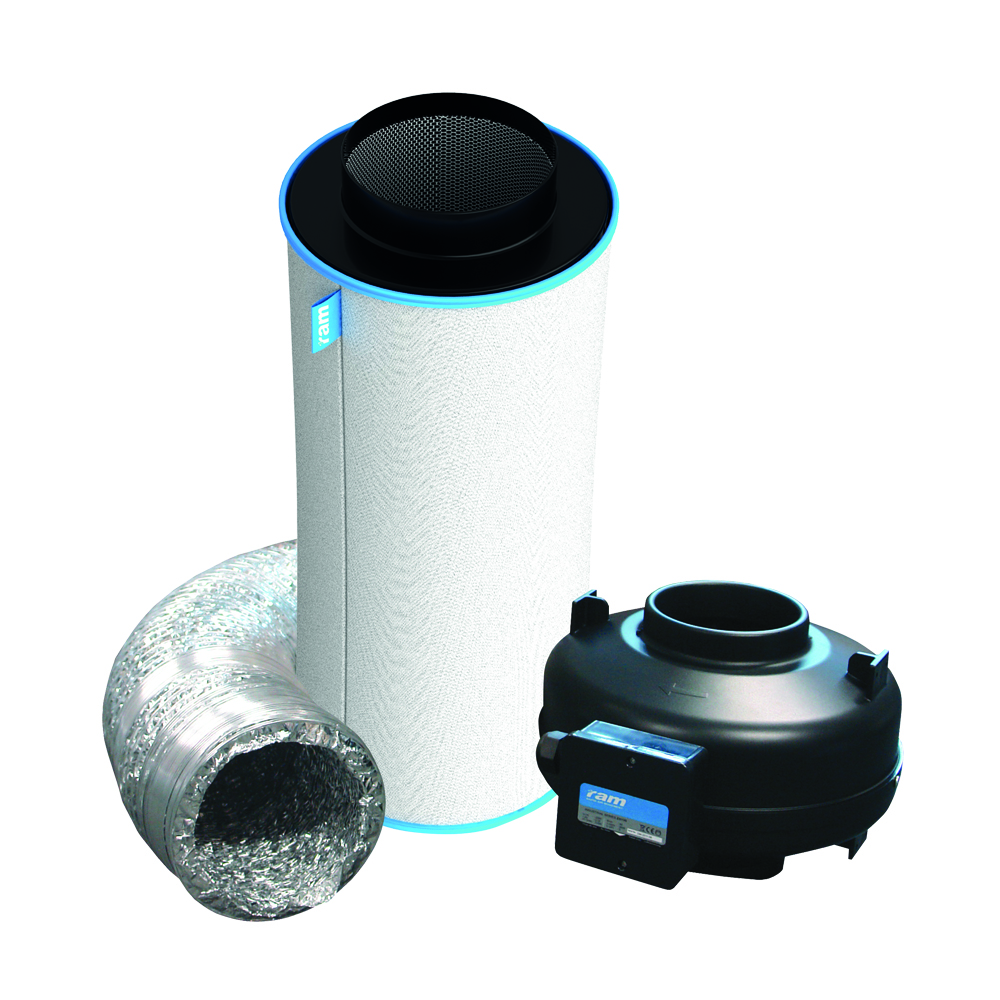

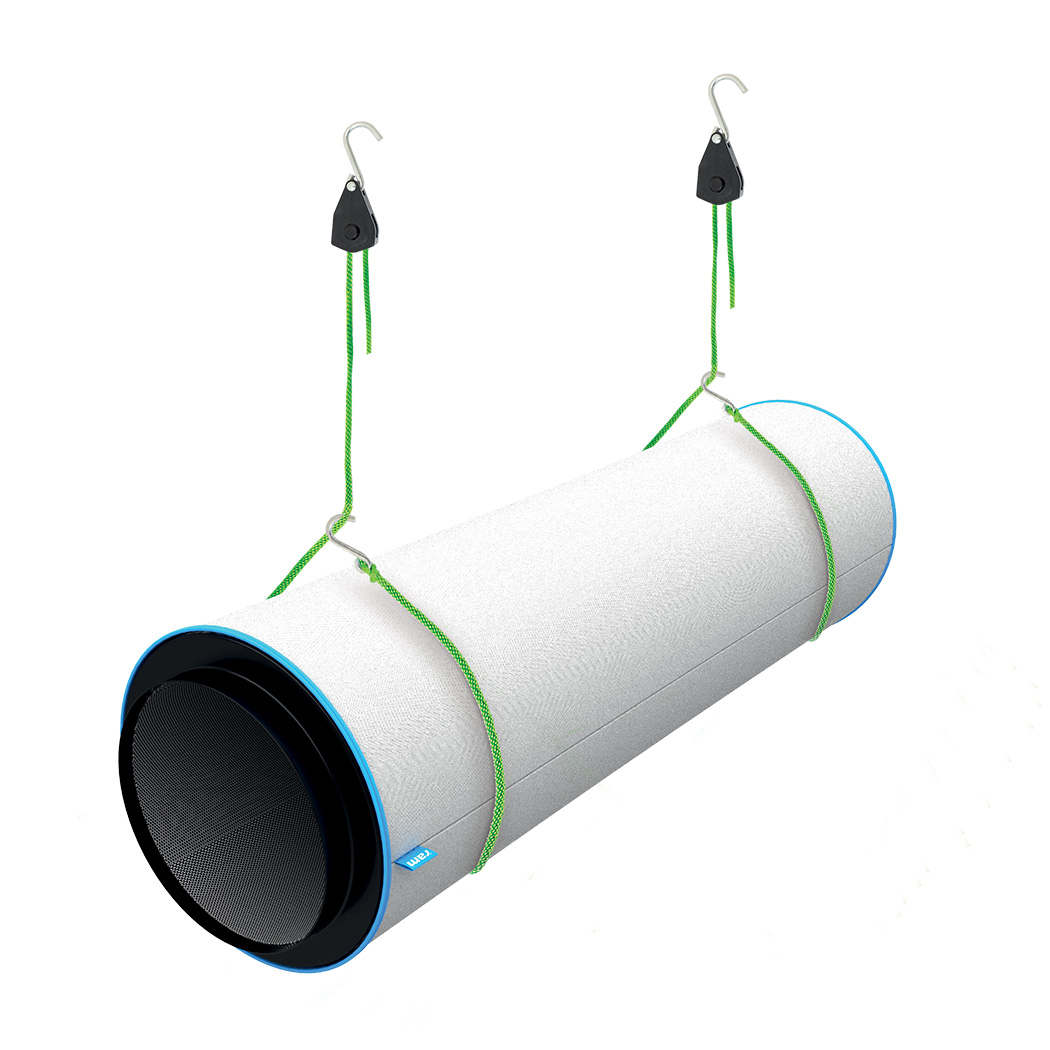

The tent has four cable entry glands, all double-lined and light tight when the toggles are tightened. Near the base there are six mite-proof passive air vents, with Velcro-fastened light proof covers if not in use. There are four 300mm inline socks (two at each side) for fitting air-cooled lighting, but these are not needed for LED lighting, so they will remain sealed by their Velcro-fastened covers. Two huge doors give access at the front of the tent, and there are also doors at each side and one at the rear. All are fastened with Tivax double-lined, lightproof zippers. If more access was ever required, the whole front of the tent can be opened by simply unzipping it.Active ventilation will be no problem. Negative pressure ventilation is preferable to avoid the possibility of odour leakage, and an excellent ventilation system can be devised using RAM Air Kit (998m³/hr) – 200mm which comprises a 200mm filter and fan and 5m of ducting. The tent is provided with enough hanger poles and straps to mount the filter within the tent in line with any of the side ventilation socks. The 200mm fan is then set up to extract air from the tent via the filter. With a smaller RAM Inline Duct Fan – 150mm - 580M³/Hr delivering air to a low-level ventilation sock at a lower rate, negative pressure conditions are created within the tent and all air exiting the tent is forced to pass through the filter.Next the four PowerPlant 650W LED Fixtures are installed. These powerful LED fixtures were chosen mainly on account of their excellent light coverage. Only about 120cm x 110cm when hung, they will evenly light a canopy area approximately 1.5m square, if positioned around 30cm above the canopy top. Also, the output PAR (Photosynthetic Active Radiation – the light energy supplied at wavelengths useful to the plants) from Samsung 3000 K & 6500 K and Osram 660 nm chips is slightly better than a regular 1000W HPS lamp, and above 80% of the PAR of a 400V 1000W double-ended lamp, although they are rated at just 650 Watts. Along with that obvious power efficiency, these units produce less heat and so can be hung closer to the canopy than an HID lamp without scorching the plants. The fixtures are dimmable and can be run as an array from a controller. For this simple set-up, however, it’s convenient to run them from a LUMii BLACK 4-Way Contactor Timer and dim them as required using the manual controls.Hanging the PowerPlant 650W LED Fixtures is simple. First, place them on the floor of the tent, LEDs facing downward. Using the hanging slings supplied, attach them to a pair of LUMii Rope Ratchets, suspended from the tent frame hanging bars. When secured, use the Rope Ratchets to hoist the fixtures to the required height. As the plants progress, the height of the fixtures above the canopy to be adjusted appropriately.

The tent is spacious, so there is plenty of room for a heater to be placed within it. But it would be a shame to waste that LightHouse 3kW Greenhouse Heater. If it is positioned outside the tent, adjacent to the air intake fan, heated air will be drawn into the tent, and the space in the lock-up outside the tent will also be heated. That will create a warm buffer to defend the tent against sudden cold snaps and provide a welcoming glow to anyone visiting for the purpose of checking and maintaining the grow. Two power settings and a sensitive thermostatic control allow the heater to be set to hold the required temperature within a degree or two. To make certain that the heat settings are correct before the plants are installed, any necessary adjustments can be made now while the tent is empty.

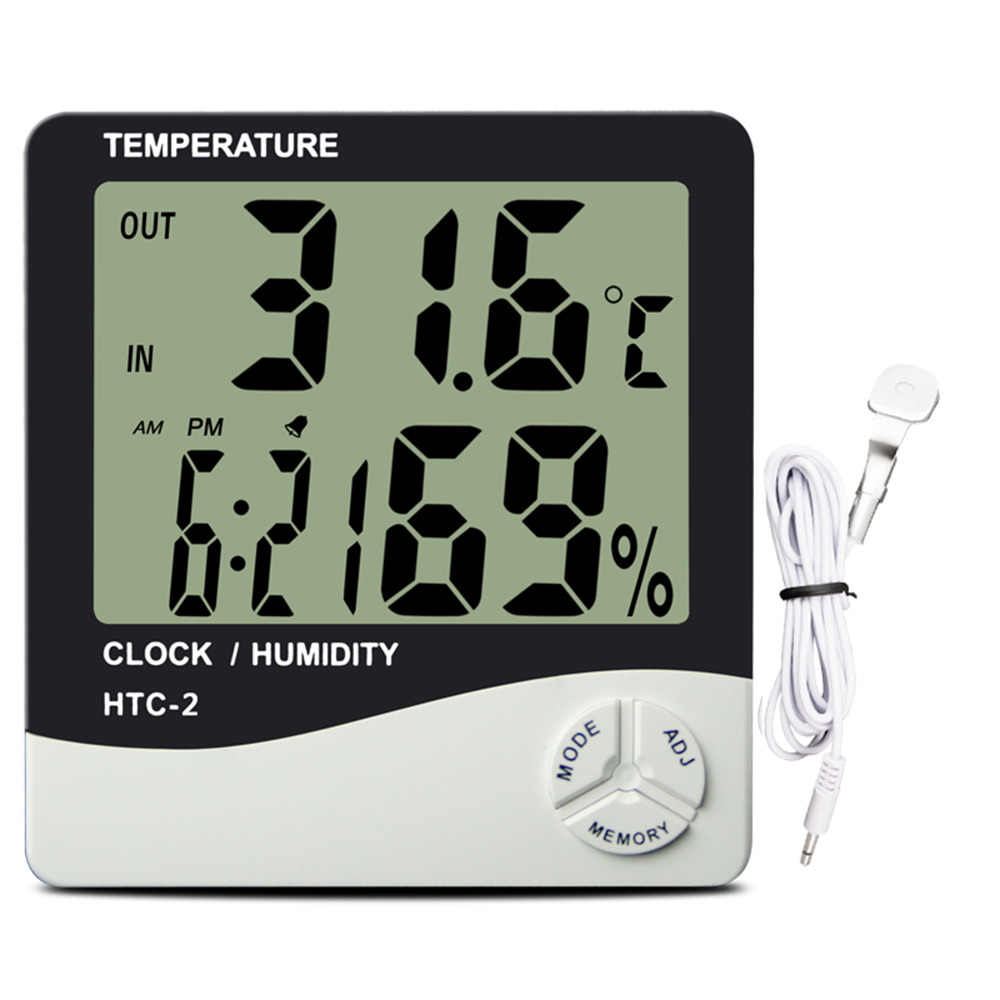

The temperature within the tent can be monitored using a Digital Series Indoor/Outdoor Min Max Thermometer. If the thermometer is hung from the tent frame at the same height as the canopy, and the waterproof “outdoor” probe (often used for checking nutrient temperatures in reservoirs) is allowed to sit at the bottom of the tent, then comparing the two readings gives a good idea of how even the temperature is throughout the tent. The maximum and minimum values are automatically recorded and can be viewed when convenient. If there is too great a difference between the temperature at the top and bottom of the grow, then this can be corrected by installing a fan to move and stir the air within the tent. A RAM 30cm (12") Air Circulator - 3 Speed should do the trick.With all of that work complete, it’s time to put the kettle on again, sit back and relax. There are a few weeks left to check out the options for potting, watering and feeding the plants when they’re ready for the big tent.

The temperature within the tent can be monitored using a Digital Series Indoor/Outdoor Min Max Thermometer. If the thermometer is hung from the tent frame at the same height as the canopy, and the waterproof “outdoor” probe (often used for checking nutrient temperatures in reservoirs) is allowed to sit at the bottom of the tent, then comparing the two readings gives a good idea of how even the temperature is throughout the tent. The maximum and minimum values are automatically recorded and can be viewed when convenient. If there is too great a difference between the temperature at the top and bottom of the grow, then this can be corrected by installing a fan to move and stir the air within the tent. A RAM 30cm (12") Air Circulator - 3 Speed should do the trick.With all of that work complete, it’s time to put the kettle on again, sit back and relax. There are a few weeks left to check out the options for potting, watering and feeding the plants when they’re ready for the big tent.

Español

Español

Français

Français